How the Optical Fibre Diameter Analyser Plays a Vital Role in Enhancing Fibre Optic Technologies

How the Optical Fibre Diameter Analyser Plays a Vital Role in Enhancing Fibre Optic Technologies

Blog Article

Just How an Optical Fibre Diameter Analyser Boosts High Quality Control in Fibre Manufacturing

The assimilation of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes represents a significant development in high quality control methodologies. By supplying real-time, exact measurements of Fibre diameters, this modern technology deals with the crucial requirement for consistency in production requirements. With its capacity to quickly identify variances and timely rehabilitative procedures, the analyser not only improves item dependability but likewise adds to general operational performance. As industries significantly prioritize high quality and compliance, comprehending the complete impact of such technologies comes to be necessary. What implications could this have for the future of Fibre manufacturing?

Importance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is important in the field of optical Fibre innovation, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre influences its light-carrying capability, depletion, and total transmission efficiency. Accuracy in gauging Fibre Diameter makes sure that the optical buildings are kept within defined resistances, which is essential for optimum signal stability.

Variations in Fibre Diameter can bring about boosted losses because of scattering and modal dispersion, affecting the quality of data transmission. In high-speed interaction systems, such disparities can lead to considerable degradation of signal top quality, bring about data errors and reduced efficiency. Constant Fibre Diameter is necessary for compatibility with ports and splicing technologies, which are indispensable parts of Fibre optic networks.

Quality control processes in Fibre production greatly depend on accurate Diameter measurements to make certain compliance with industry requirements. By implementing durable measurement strategies, producers can enhance item reliability, lessen waste, and improve total system performance. Therefore, the importance of Fibre Diameter measurement can not be overemphasized, as it works as a keystone in the development of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Functions

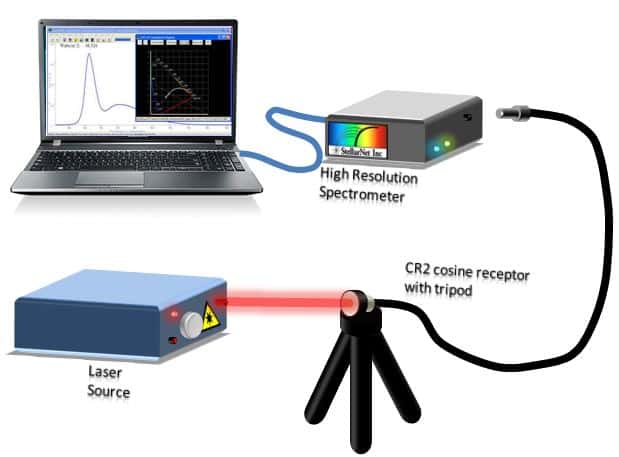

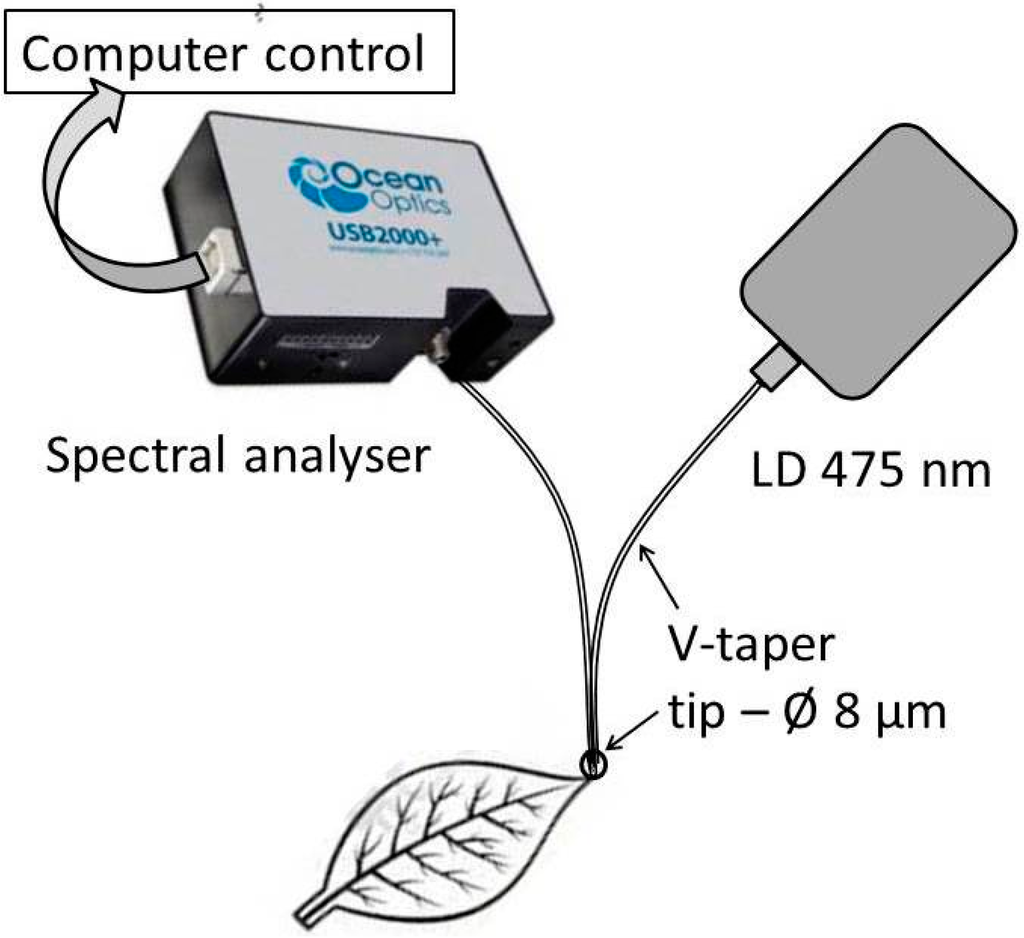

The effective measurement of Fibre Diameter counts on sophisticated logical techniques that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser innovation and progressed image processing formulas to properly evaluate the Diameter of fibers as they are produced

At first, a laser light beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser captures this shadow utilizing high-resolution cams placed strategically along the manufacturing line. The captured images are then refined in real-time to figure out the Fibre's Diameter with extraordinary precision.

The system makes use of innovative formulas that represent numerous variables, consisting of variants in light strength and ecological problems, to boost measurement dependability. It can identify minute changes in Diameter, such as changes that might occur during the manufacturing process.

In addition, the analyser can taking care of numerous fibers all at once, raising throughput without jeopardizing accuracy. By offering instantaneous responses on the Diameter, the Optical Fibre Diameter Analyser plays a vital function in maintaining stringent quality assurance criteria, making certain that the end product fulfills industry requirements and consumer demands.

Benefits of Real-Time Surveillance

While standard methods of monitoring Fibre Diameter often entail taxing post-production checks, real-time tracking considerably enhances the performance and high quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique allows suppliers to determine deviations in Fibre Diameter as they take place, rather than waiting till production is full to examine quality

By continually measuring go to the website the Diameter throughout production, suppliers can guarantee that the fibers meet rigorous specifications, bring about decreased irregularity and improved consistency. Real-time surveillance also allows prompt rehabilitative actions to be taken, lessening waste and preventing faulty fibers from entering the supply chain.

Additionally, this modern technology facilitates enhanced data collection and evaluation, providing insights right into manufacturing trends and prospective locations for renovation. Such data-driven decision-making empowers producers to maximize processes and preserve high criteria of quality control.

Additionally, real-time tracking cultivates a society of continuous improvement within the production environment. Staff members are a lot more involved when they can see the influence of their operate in real-time, resulting in increased liability and a dedication to excellence. Overall, the implementation of real-time tracking systems in optical Fibre manufacturing translates to exceptional product high quality and boosted client contentment.

Effect On Manufacturing Performance

Applying optical Fibre Diameter analysers significantly enhances production performance by streamlining the production procedure. These tools assist in constant tracking of Fibre Diameter, enabling producers to discover discrepancies in real-time. By identifying inconsistencies promptly, assembly line can be readjusted swiftly, lessening downtime and decreasing the probability of creating defective products.

In addition, the combination of these analysers into the manufacturing operations allows better source allowance. With precise Diameter dimensions, operators can enhance product usage, making certain that sources are not squandered on mistaken fibers. This precision additionally adds to less scrap and revamp, ultimately decreasing production prices.

The automation supplied by optical Fibre Diameter analysers minimizes reliance on hand-operated evaluations, which are susceptible and frequently taxing to human error. Therefore, employees can concentrate on even more tactical jobs, enhancing general performance.

Furthermore, the information generated from these analysers can notify procedure enhancements and promote better decision-making. By assessing patterns in Fibre Diameter variants, suppliers can execute positive actions to enhance production strategies and maintain constant high quality. In recap, optical Fibre Diameter analysers play an important duty in increasing manufacturing efficiency, causing better outcome and increased profitability.

Study and Success Stories

Throughout over at this website numerous sectors, study highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One famous instance is a leading telecommunications company that faced difficulties with inconsistent Fibre diameters, causing raised denial prices. By incorporating an optical Fibre Diameter analyser, the company accomplished real-time tracking of Fibre dimensions, leading to a 30% decrease in flaws and considerable expense financial savings.

Furthermore, a study organization concentrating on sophisticated materials used optical Fibre Diameter analysers to refine their speculative processes. The analyser's capability to supply detailed understandings into Fibre uniformity allowed the growth of ingenious products with enhanced efficiency qualities.

These success stories highlight the vital role of optical Fibre Diameter analysers in enhancing quality assurance, improving manufacturing performance, and driving development throughout diverse markets.

Verdict

To conclude, the Optical Fibre Diameter Analyser plays a pivotal duty in boosting high quality control within Fibre production. By supplying precise, real-time dimensions and helping with immediate restorative actions, this innovation dramatically reduces variability and minimizes waste. The application of such innovative tools fosters a culture of constant renovation and functional efficiency, ultimately making sure conformity with sector criteria and maintaining competitiveness. As demonstrated with numerous instance researches, the analyser proves important for accomplishing remarkable item top quality in Fibre production.

The implementation of optical Fibre Diameter analysers enabled for strict top quality control, guaranteeing that the produced fibers met exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays a pivotal function in enhancing high quality control within Fibre production.

Report this page